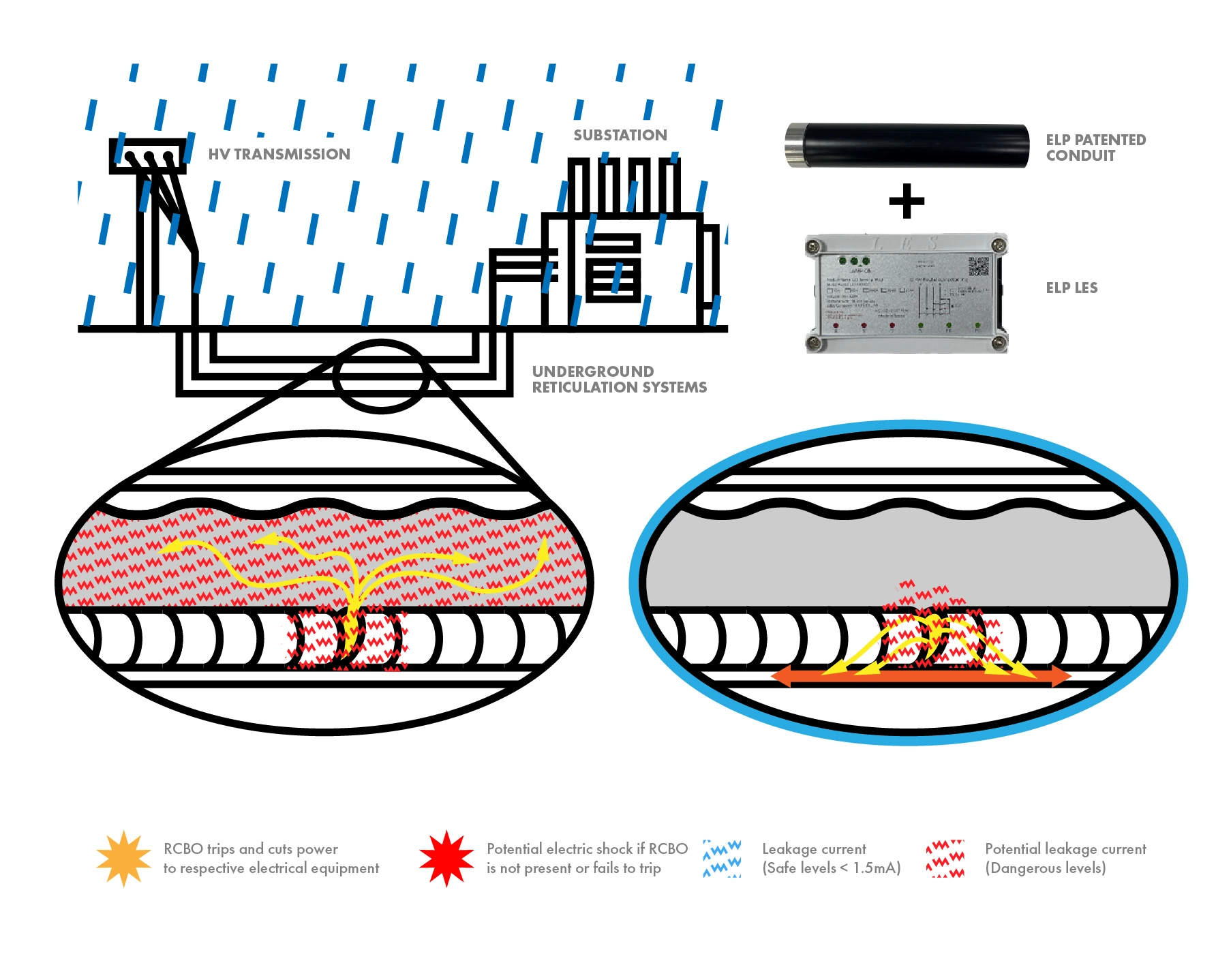

ELP has a solution for this problem. ELP have developed a patented technology that will collect all the leakage current from the cable and raise the alarm for this issue. This conduit which was specifically developed for these applications, acts as the collector and path for all stray currents (leakage current and induced current) to flow back to the ELP eLynX device that is connected to the conduit at one end or both ends of the conduit.

The benefits are:

- All lost energy is collected and injected back into the mains, resulting in no energy loss and no revenue loss.

- The ELP solution identifies the earliest signs of issues on the cable as it detects the smallest leakage current, and isolates the location of the issue.

- Allows operators to plan a replacement for the cable, preventing an unforeseen trip and loss of power for an extended amount of time.

- All resulting in preventing a significant loss of energy, down time and financial losses.